These days, gun owners have various coating options, ranging from bluing to Cerakote to Parkerizing. Each of these coating options has its own unique properties and benefits. The process of choosing the right type of coating depends on many factors. Decide the amount of money you are willing to spend on the firearm coating. Other factors include the quality of the piece and the expected environment in which you will be using your firearm. Each type of firearm coating is qualified for some specific applications. You’ll find differences in each one of them on their levels of effectiveness, corrosion protection, longevity, and durability.

In this article.

1. Gun Bluing: It is also known as steel bluing; it is a process by which the metal of the firearm is given a rust-resistant finish. It is simply achieved with the help of an electrochemical process; the iron present in the steel is converted to magnetite (black oxide). This process provides alone a minimal amount of rust protection to your gun. In order to ensure maximum corrosion protection, you’ll require frequent light oiling or some other kind of protective treatment.

2. Parkerizing: This process includes the submersion of firearm steel into a phosphoric acid solution. It protects the steel surface of the firearm from corrosion and helps in increasing its overall resistance to scratches and nicks. Phosphating and bonderizing are some other popular names used for Parkerizing. Copper and chlorates are often added to zinc or manganese to create a Parkerizing solution. This Parkerizing solution is then heated at high temperatures of about 190-210 degrees Fahrenheit. You’ll find streams of tiny bubbles rising from the metal part of the firearm during the Parkerizing process of the firearm. The streams of bubbles will cease eventually as the process completes.

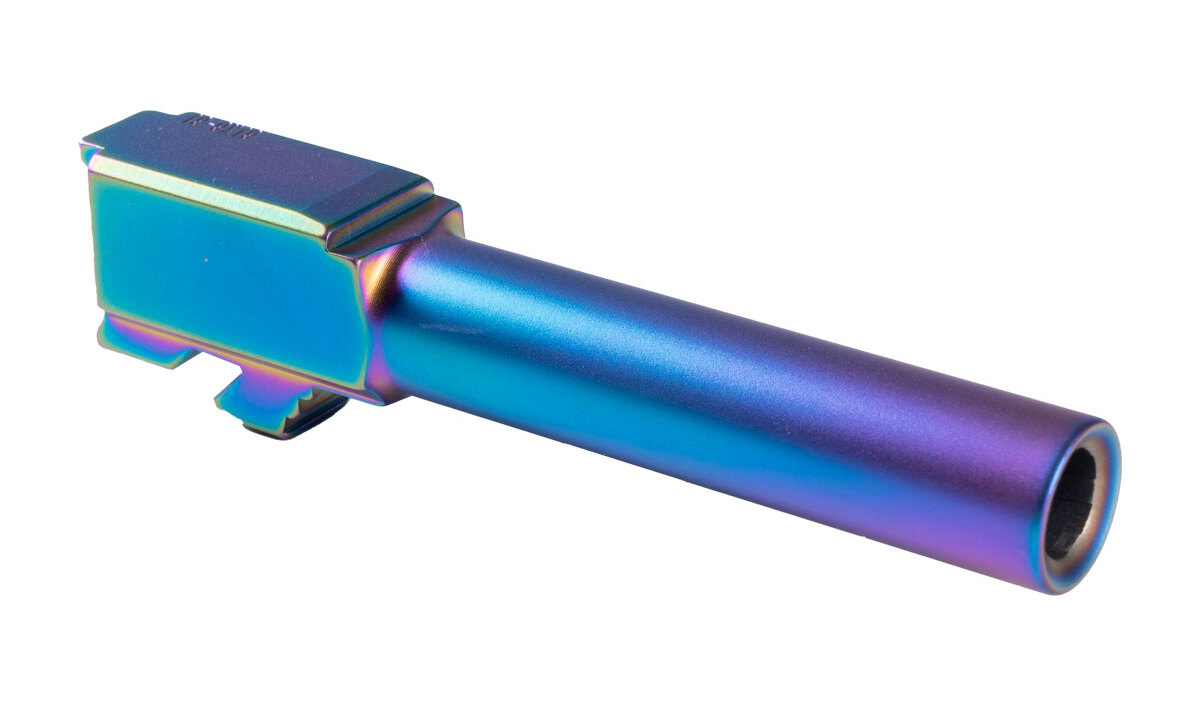

3. Anodizing: This process is used to increase the thickness of the layer of natural oxide on the metal surface of the firearm. For the reaction to take place successfully, the piece of the firearm that needs to be treated becomes the anode electrode. It increases the overall lubricity of the firearm and also leads to an improved adhesive surface for glues, paint primers, etc. The process of gun anodizing leads to a dimensional increase in the piece that was treated. Sulphuric acid is used as the most common electrolyte used in the anodizing process.

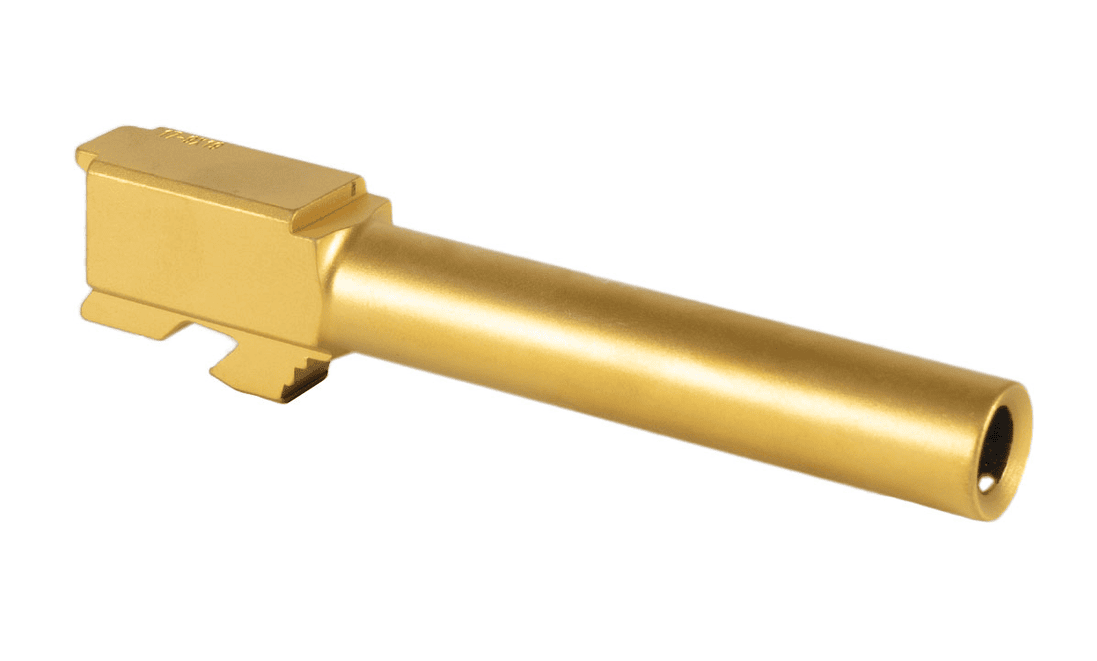

4. Cerakote: It is a ceramic-based coating used for firearms and is available in various colors. If you are looking forward to custom-color your firearm, then Cerakote is one of the simplest finishing options available in the market today. The best thing about choosing the Cerakote coating is that it offers a higher level of lubricity to the treated parts of the firearm. Cerakote is known for its superb properties like heat reduction and resistance towards scratches. Cerakote coating can be applied to various types of materials like metal, plastic, composite surfaces, etc. It lasts for years when treated with little maintenance.