The Glock 19, 23, and 32 are among the most popular handguns in the world, known for their reliability, ease of use, and versatility. As with any firearm, enthusiasts often seek ways to enhance performance, improve handling, and customize their weapons to better suit their needs. Upgrading components is a common practice among gun owners, and one of the most impactful modifications is the installation of a stainless steel guide rod.

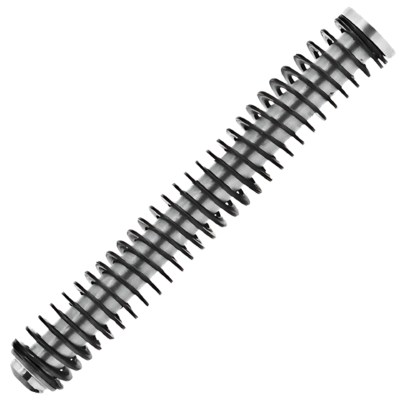

This seemingly simple upgrade can significantly affect the firearm’s performance, recoil management, and overall shooting experience. The guide rod plays a crucial role in the operation of semi-automatic pistols, including the Glock series. It serves as a stabilizing component that helps manage the recoil spring’s function during the cycling of the slide.

While factory guide rods are typically made from polymer or aluminum, stainless steel guide rods offer enhanced durability and performance. This article will delve into the benefits of upgrading to a stainless steel guide rod, provide installation instructions, compare it to factory options, and discuss the importance of recoil springs in Glock models 19, 23, and 32.

Key Takeaways

- Upgrading your Glock 19/23/32 with a stainless steel guide rod can improve performance and durability.

- Benefits of using a stainless steel guide rod include reduced recoil, improved accuracy, and increased lifespan of the firearm.

- Installing a stainless steel guide rod in your Glock 19/23/32 is a simple process that can be done at home with basic tools.

- When comparing stainless steel guide rods to factory guide rods, the former is often found to be more reliable and long-lasting.

- The recoil spring plays a crucial role in the function of your Glock 19/23/32, and upgrading to a stainless steel guide rod can enhance its performance.

- Proper maintenance and care for your upgraded Glock 19/23/32, including regular cleaning and lubrication, is essential for optimal performance.

- User reviews and feedback on stainless steel guide rod upgrades are overwhelmingly positive, with many reporting noticeable improvements in shooting experience.

- In conclusion, upgrading to a stainless steel guide rod is worth it for those looking to enhance the performance and longevity of their Glock 19/23/32.

Benefits of Using a Stainless Steel Guide Rod

One of the primary advantages of upgrading to a stainless steel guide rod is its increased durability compared to factory options. Stainless steel is inherently more robust than polymer or aluminum, which means it can withstand greater wear and tear over time. This durability translates into a longer lifespan for the guide rod itself, reducing the need for frequent replacements.

Additionally, stainless steel is less prone to bending or warping under stress, which can lead to improved reliability during operation. Another significant benefit of stainless steel guide rods is their ability to enhance recoil management. The added weight of a stainless steel guide rod can help mitigate muzzle rise during rapid fire, allowing for quicker follow-up shots.

This is particularly advantageous for competitive shooters or those who engage in defensive shooting scenarios where speed and accuracy are paramount. The increased mass can also contribute to a more stable shooting platform, improving overall control and precision.

How to Install a Stainless Steel Guide Rod in Your Glock 19/23/32

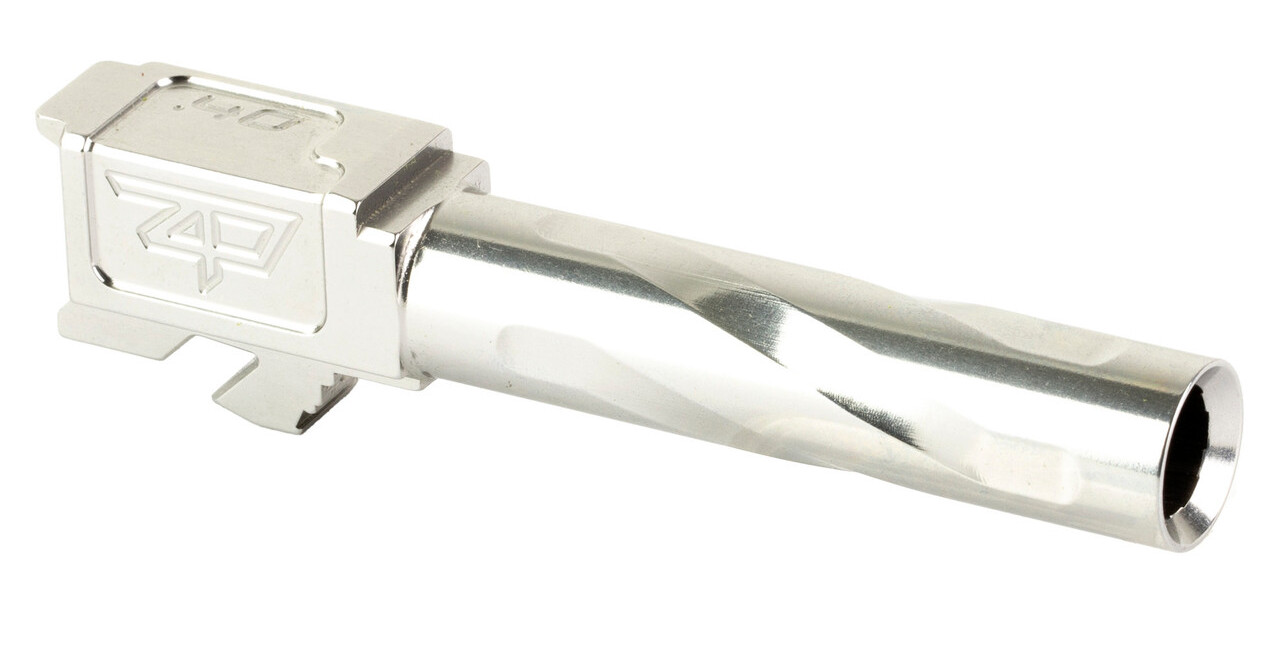

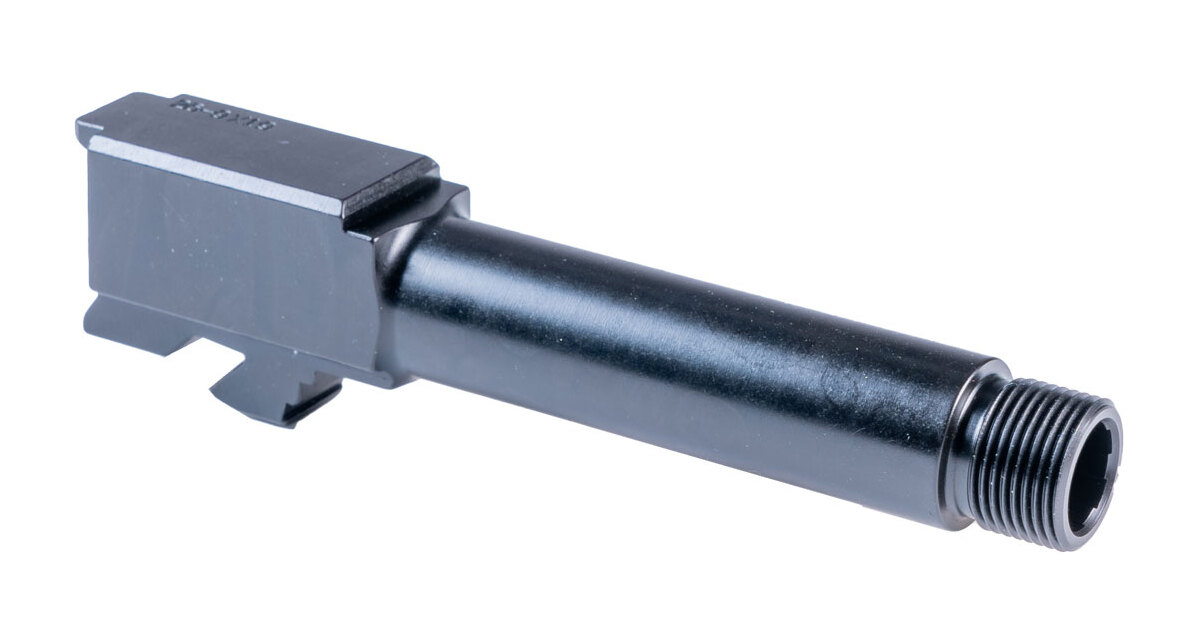

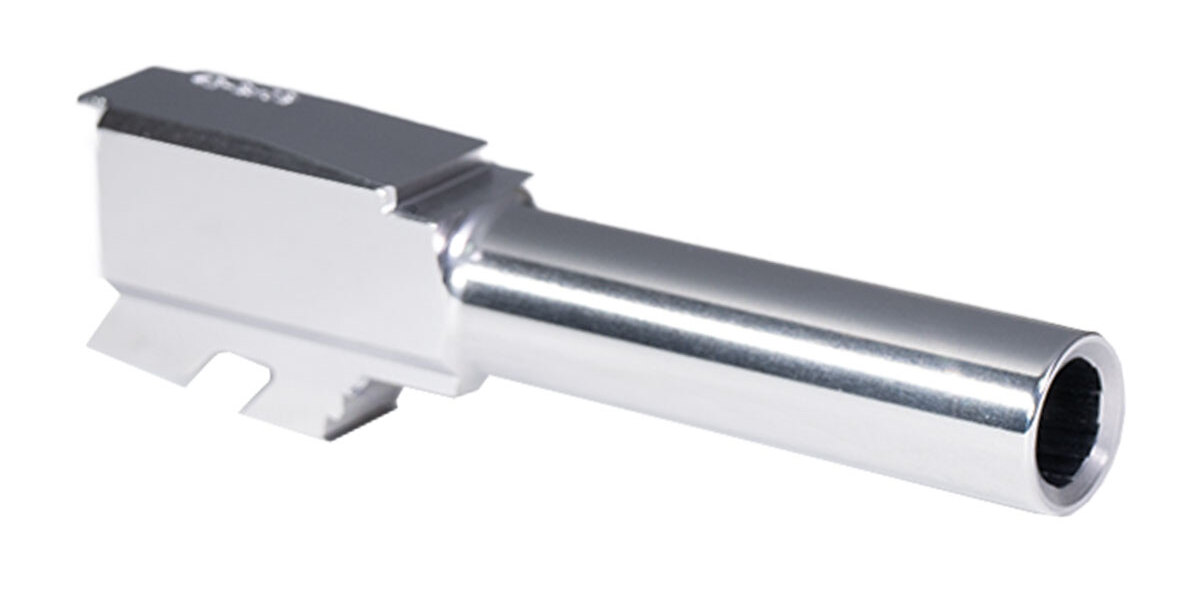

Upgrade Your Glock: Stainless Steel Guide Rod for Gen 1–3 G19/23/32

Installing a stainless steel guide rod in your Glock 19, 23, or 32 is a straightforward process that can be accomplished with minimal tools. Before beginning the installation, ensure that your firearm is unloaded and that you are working in a safe environment. Start by disassembling your Glock according to the manufacturer’s instructions.

This typically involves removing the magazine, clearing the chamber, and pulling the trigger while simultaneously pulling down on the slide lock to separate the slide from the frame. Once you have disassembled your Glock, remove the factory guide rod and recoil spring assembly from the slide. This can usually be done by gently pulling it out from its housing.

Take your new stainless steel guide rod and recoil spring assembly and insert it into the slide in the same manner as the factory component. Ensure that it is seated properly and that the spring is aligned correctly with the slide’s internal structure. After installing the new guide rod, reassemble your Glock by sliding the upper assembly back onto the frame.

Make sure everything is aligned correctly before locking it back into place. Once reassembled, perform a function check to ensure that everything operates smoothly. This includes racking the slide several times and checking for proper cycling of the action.

If everything feels right, you are ready to take your upgraded Glock to the range.

Comparing Stainless Steel Guide Rods to Factory Guide Rods

When comparing stainless steel guide rods to factory options, several factors come into play that can influence a shooter’s decision. One of the most notable differences is weight. Factory guide rods are often made from lighter materials like polymer or aluminum, which can result in less overall mass in the firearm.

While this may be beneficial for some users who prefer a lighter carry gun, it can also lead to increased muzzle rise during rapid fire due to less inertia counteracting recoil. In contrast, stainless steel guide rods provide additional weight that can help stabilize the firearm during shooting. This added mass can absorb some of the energy generated during recoil, allowing for better control and quicker follow-up shots.

However, it’s essential to consider personal preferences when making this choice; some shooters may prefer the lighter feel of factory guide rods for everyday carry or extended periods of use. Another aspect to consider is durability and maintenance. Factory guide rods may require more frequent replacement due to wear over time, especially if subjected to heavy use or high round counts.

Stainless steel guide rods are generally more resistant to wear and tear, making them a more long-term investment for serious shooters. Additionally, they are easier to clean and maintain since stainless steel does not corrode as easily as other materials.

Understanding the Role of the Recoil Spring in Your Glock 19/23/32

The recoil spring is an integral component of any semi-automatic pistol, including Glock models 19, 23, and 32. Its primary function is to absorb and manage the energy generated during firing, allowing for smooth cycling of the slide and reliable ejection of spent casings. The recoil spring works in conjunction with the guide rod to ensure that the slide returns to its original position after firing a round.

In Glock pistols, the recoil spring is designed with specific tension levels that correspond to the caliber and intended use of the firearm. For example, a Glock 19 chambered in 9mm will have a different recoil spring tension than a Glock 23 chambered in .40 S&W. Upgrading to a stainless steel guide rod often necessitates considering whether to also upgrade or replace the recoil spring itself.

Many aftermarket guide rods come with springs designed for optimal performance with their specific weight and configuration. Understanding how these components interact is crucial for achieving reliable performance from your Glock. A mismatched recoil spring can lead to issues such as failure to feed or eject properly, which can be detrimental in critical situations.

Therefore, when upgrading your guide rod, it’s essential to ensure that you are using compatible recoil springs that match your shooting style and intended use.

Maintenance and Care for Your Upgraded Glock 19/23/32

Upgrade Your Glock: Stainless Steel Guide Rod for Gen 1–3 G19/23/32

Proper maintenance is vital for ensuring that your upgraded Glock 19, 23, or 32 continues to perform at its best over time. After installing a stainless steel guide rod, it’s essential to incorporate it into your regular cleaning routine. Unlike polymer components that may wear down or degrade over time, stainless steel requires different care due to its unique properties.

Cleaning your stainless steel guide rod involves using appropriate solvents and brushes designed for metal surfaces. Regularly inspect it for signs of wear or corrosion; while stainless steel is resistant to rusting, it can still accumulate fouling from gunpowder residue or other contaminants. A simple wipe-down with a clean cloth after each range session can help maintain its appearance and functionality.

Additionally, pay attention to your recoil spring’s condition as well. Springs can lose tension over time due to repeated compression and decompression cycles. If you notice any signs of wear or if your firearm begins experiencing feeding issues or malfunctions, it may be time to replace both the recoil spring and guide rod assembly.

Keeping spare parts on hand can ensure that you are always prepared for any maintenance needs that arise.

User Reviews and Feedback on Stainless Steel Guide Rod Upgrades

User feedback on stainless steel guide rod upgrades tends to be overwhelmingly positive among those who have made this modification to their Glocks. Many shooters report noticeable improvements in accuracy and control when using a stainless steel guide rod compared to factory options. The added weight often translates into reduced muzzle rise during rapid fire scenarios, allowing for quicker follow-up shots—a critical factor for competitive shooters or those practicing self-defense techniques.

Some users have also noted that their firearms exhibit smoother cycling with stainless steel guide rods installed. This smoother operation can lead to increased reliability during high-stress situations where every shot counts. However, it’s important to note that experiences may vary based on individual shooting styles and preferences; some users may prefer lighter setups for everyday carry or extended shooting sessions.

While most reviews highlight positive experiences with stainless steel guide rods, some users express concerns about potential compatibility issues with certain aftermarket components or modifications. It’s essential for prospective buyers to research compatibility with their specific model and any other upgrades they may have made before purchasing a stainless steel guide rod.

Is Upgrading to a Stainless Steel Guide Rod Worth It?

The decision to upgrade your Glock 19, 23, or 32 with a stainless steel guide rod ultimately depends on individual preferences and intended use cases. For those seeking enhanced durability, improved recoil management, and smoother operation during shooting sessions, this upgrade can be well worth it. The benefits of increased weight and stability often translate into better performance on the range or in defensive situations.

However, it’s crucial for gun owners to consider their specific needs when making modifications to their firearms. While many users report positive experiences with stainless steel guide rods, others may find that factory options better suit their preferences for weight and handling characteristics. Ultimately, understanding how these components work together within your Glock will help you make an informed decision about whether upgrading is right for you.

If you’re considering upgrading your Glock with a stainless steel guide rod for Gen 1–3 G19/23/32, you might also be interested in enhancing your shooting accuracy with a red dot sight. Red dot sights can significantly improve target acquisition and precision, making them a popular choice among firearm enthusiasts. For more information on how to select the right red dot sight for your needs, check out this related article on purchasing a red dot. This guide will help you understand the benefits of red dot sights and how to choose the best one for your Glock or any other firearm.